Tote Washers / Tank Washers

|

|

Tote Washers / Tank Washers / Bin Washers

A tote washing system is an automated machine meant to clean and sanitize intermediate bulk containers (IBCs) – also called totes – which are commonly used in various industries for storing and transporting bulk materials.

Industries Benefiting from Tote Washers

➔Food Processing: In the food industry, tote washers maintain hygiene by cleaning containers that hold food ingredients.

➔Pharmaceuticals: Tote washers are used here for sanitizing containers that carry raw materials and finished goods, keeping high cleanliness standards.

➔Chemical Industry: These machines are indispensable for the chemical industry to cleanse containers of chemicals, keep up content purity, and prevent contamination.

➔Automotive Manufacturing: The automotive sector makes the most of tote washers for the sanitization of parts and components containers.

➔Material Handling: Tote cleaning machines are used in warehousing and logistics for maintaining the hygiene of goods storage and transport containers.

➔Paints, Oils, and Solvents: Facilities dealing with these substances rely on tote washers for container cleaning and material recovery.

SRS for Tote Washing Solutions

SRS is a leading provider of tote washer machines with extensive solutions meeting specific industrial demands.

Be it a dunnage or an industrial tote cleaning machine, SRS holds the expertise and experience to deliver high-quality, efficient, and customer-focused solutions.

Collaborate with us to find a suitable cleaning solution for your operations

SRS Engineering offers the TW-Series (tote washer / tank washer) designed to work with metal or plastic totes or tanks with maximum opening of 80.

These heavy duty automatic tote washing systems (TW-Series or CTW-Series -designed for larger volume washing), were specifically designed to wash interior surfaces of totes, tanks, mixers, churns, and kettles. The TW-Series washer was designed for cleaning applications in pharmaceutical, food, chemical, coatings, paint, resin, and petroleum industries to effectively remove paint and coatings, adhesives, inks and dyes. (For optional exterior surface washing applications see the MW-Series washer) The TW-Series washer can wash up to 80″ fixed and non fixed kettles, IBCs, totes, tanks, and mixer tanks in both metal or plastic construction. The high pressure pumps and high impingement jet spray nozzles are designed to remove even the most difficult residues from containers including cured resins and paints as well as cured road paint (Water &Solvent Based). The TW-Series is used in solvent, caustic, and water wash systems and utilizes Closed-Loop configurations to minimize waste water or solvent.

SRS Engineering’s TW-Series Applications:

- Tote washing

- Tank washing

- IBC washing

- Mixer washing

- Kettle washing

- Churn washing

For larger volumes requiring a conveyorized unit see the CTW-Series Washers (Conveyorized Tote Washers)

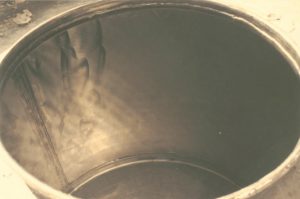

Tote Before (Contaminated w/ Paint) |

Tote After |

An easy to use, set up menu provides the operator with the ability to program a wash and rinse cycle into the PLC microprocessor logic controller allowing the system to operate automatically. The controller monitors a series of relays and contacts to verify proper liquid levels, flows, pressures, container security and proper grounding, before starting the cycle. Any fault condition is diagnosed and clearly displayed on the control panel to ensure operator safety and ease of operation. The system automatically shuts off in the event of a fault condition or at the end of the cycle.

TW-Series Features and Options:

- PLC Microprocessor Controller in NEMA 4x Enclosure

- Solvent, Caustic, Sanitizer, and Water washing

- Explosion resistant, ATEX, and Zone 0 models available

- Hydraulically or pneumatically operated Wash Head Assembly

- Stainless or Carbon steel (Mild Steel) construction

- Triple rinse applications

- Nitrogen or CO2 Purging

- Fixed or movable system

- Exhaust systems

- VOC Containment

- High pressure wash cycles

- Tilting base for flat bottom type vessels

- Multi-head configuration for washing multiple sized tank openings, and baffle tanks for sludge or oil separation.

- Pre-wired for field installation

Read more about the TW-Series designed for wash applications such as Industrial Tote Washing, Tank Washing, Mixer Washing, Kettle Washing, Churn Washing and various other similar washings. For larger volume washing needs requiring a conveyorized washing unit, see our CTW-Series Conveyorized Washers.

To View Printable PDF Version of this Page ![]()

SRS Engineering Corporation is the leading manufacturer of Automatic Washing and Cleaning Systems for totes, tanks and bins. The TW-Series (Tote Washer, Tank Washer and Bin Washer) was designed to be used in industries such as pharmaceutical, food, chemical, coatings, paint, resin, and petroleum industries. SRS also offers the CTW-Series (a conveyorized washer) which was made for larger volumes. Custom solutions for industrial tote, tank and bin washing are also available.