Washing Systems

Industrial Washing Systems

SRS Engineering Corporation is the leading manufacturer of Automatic Washing and Cleaning Systems for numerous industrial applications. We provide a wide range of washing applications specifically designed to fulfill common and custom parts or container applications in industrial applications including but not limited to solvent, caustic, sanitizer, and aqueous applications.

SRS’ washing systems utilize high pressure pumps and spray nozzles in all of their industrial washing systems. This high impingement spray technology is specially designed to eliminate even the toughest cured resins, paints, inks, and much more.

Washing Applications:

|

|

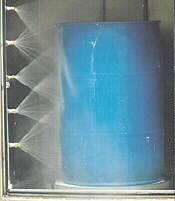

Drum Washers – Barrel WashersThis drum washing system was designed to clean large drums, barrels, and overpaks of all sizes. The high impingement jet spray technology can clean both interior surfaces, exterior surfaces, or both. Read more about SRS’ Drum Washers SRS offers two drum washers currently approved by the U.S. General Services Administration (GSA) |

|

|

|

Pail Washers – Bucket WashersThis washing system was designed to clean smaller containers such as pails, buckets, jars, lids, cans, and other small parts. High pressure sprayers can clean both interior and exterior surfaces. Read more about SRS’ Pail Washers

SRS offers three pail washers currently approved by the U.S. General Services Administration (GSA) |

|

|

|

Tank WashersThis tank washer was designed to wash interior surfaces of tanks. High impingement jet spray technology can remove the most difficult residues from containers including cured resins, paints, road paint, and much more. Read more about SRS’ Tank Washers | |

|

|

Tote WashersThis tote was designed to work with both metal and plastic totes and can wash up to an 80″ opening. This heavy duty system employs high pressure pumps and sprayers to wash interior surfaces to effectively remove paint, coatings, adhesives, inks and dyes. Read more about SRS’ Tote Washers | |

|

|

Kettle WashersThis unique kettle washing system was designed to wash interior surfaces of both fixed and non fixed kettles. High impingement sprayers can remove the most stubborn coatings, resins, paints, inks and more. | |

|

|

Multi Washers (Printing Press Washers)This washing system was initially designed for the printing industry to clean large printing press parts and components, however this system can be customized to clean a multitude of different containers including drums, pails, parts, and much more. Read more about SRS’ Multi Washers | |

|

Conveyorized Washer CTW- Series The CTW-50 Series can be entirely controlled or manipulated by the PLC via an 8” color touch screen (HMI). The unit is constructed of corrosion resistant stainless steel for an added life span. The CTW-50 has saved the medical equipment company with water costs by re-circulating the wash water, thus minimizing water consumption.

Read more about SRS’ Conveyorized Washers |

SRS Industrial Washers are capable of handling:

-

Interior Surface Washing

-

Exterior Surface Washing

-

Interior & Exterior Surface Washing

-

High Pressure

-

Low Pressure

-

Unlimited Wash & Rinse Cycles

-

Air Drying

-

Heated Drying

-

Vapor Evacuation

-

Chamber & Container Purging

-

Automated Loading Systems

| UNLIMITED APPLICATIONS | TYPES OF CONTAINERS |

|

|

Watch video below to see how our washing systems operate

Washing Operations

High pressure pumps are used to spray a wash solution to remove the most difficult residues. An advanced microprocessor control (PLC) unit verifies all safety parameters before initiating the pre-programmed cycles or sequences which can include but are not limited to wash, rinse(s), sanitize, purge, exhaust, and drying cycles. While the system is in operation the main control panel has an (HMI) which displays current system status.

The HMI displays:

- Present Cycle

- Time/Date Stamp

- Operator Fault Conditions

- Part Count

- Life Cycle of System

- Components Scheduled Maintenance Tasks

- Tag Alarms with Part Numbers

- Amount of Down Time Incurred

The wash systems are fully capable of displaying other information including desired customer information, tank temperature/levels, and other auxiliary equipment information pertinent to the functionality of the system.

SRS Engineering Corporation is the leading manufacturer of Automatic Washing and Cleaning Systems for numerous industrial applications. Including drum washers, barrel washers, pail washers, bucket washers, tank washers, tote washers, and kettle washers. Additional industrial washing systems are available for printing press parts as well as specialized washing system for flexographic off press machines. SRS Engineering Corporation also offers custom washing solutions for industrial application.