Drum Washers

|

|

Drum Washers – Barrel Washers

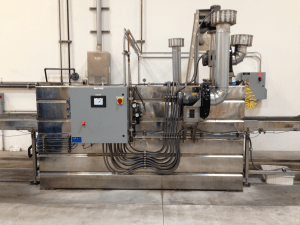

SRS Engineering’s automatic enclosed medium sized drum washer unit, the DW-Series (Drum Washer) and DWC-Series (Drum Washer/Crusher) are designed to clean larger containers including various sized 30 and 55 gallon drums, barrels, and overpaks, as well as handle small containers such as pails, buckets, jars, lids, and any other specialty parts contaminated with a wide variety of solvent or aqueous based materials. The DW-Series (Drum Washer) and DWC-Series (Drum Washer/Crusher Combination) both feature corrosion resistant, high pressure pumps and spray nozzles which can remove even the most difficult residues from the containers. The high impingement jet spray technology can even eliminate cured resins and paints. A vapor tight lid is typically used to ensure vapor containment. Interlocked lid, secure sensors, and ground proving switches are standard features to ensure maximum operator safety.

SRS Engineering’s DW-Series Drum Washers are designed for:

SRS Engineering’s DW-Series Drum Washers are designed for:

- 85 Gallon Overpak Washing

- 55 Gallon Drum and Barrel Washing

- 44 Gallon Drum Washing

- 200 Liter Drum Washing

- 30 Gallon Drum Washing

- Pail Washing

- Bucket Washing

- 20 Liter Tin Washing

- Lid Washing

- Including other Various Other Small Containers that the PW Series can wash.

For information about the DWC-Series, designed for both Drum Washing and Crushing, Click Here.

Both units have an easy to use, set up menu that provide the operator with the ability to program a wash and rinse cycle into the PLC microprocessor logic controller allowing the system to operate automatically. The controller monitors a series of relays and contacts to verify proper liquid levels, flows, pressures, container security and proper grounding, before starting the cycle. Any fault condition is diagnosed and clearly displayed on the control panel to ensure operator safety and ease of operation. The system automatically shuts off in the event of a fault condition or at the end of the cycle.

The cleaning liquid used in the primary wash cycle can also be recirculated to an external containment reservoir, tank, or built in sump tank to minimize the volume required. The rinse can then be disposed off site, recycled, or returned to a dirty wash tank as make-up (commonly used in Closed-Loop System configurations).

|

|

|

|

|

|

Watch the interior washing of a drum in action |

DW-Series Features and Options:

- Washes Interior and Exterior Surfaces

- Solvent, Caustic, Sanitizer, and Water washing

- Explosion Resistant, ATEX, and Zone 0 models available

- Electric or Pneumatically operated

- Stainless or Carbon steel (Mild Steel) construction

- Triple Rinse applications

- Automated Drum Loading Systems

- Nitrogen or CO2 Purging

- Single, dual, tri, quad, and Conveyor Configurations

- Specialty wash racks

- Exhaust system

- Heated Drying

- VOC Containment

Additional Features and Options:

- Heated or Non-Heated built in sumps

- Optional Lid Racks

- Optional Multi-part racks

- Conveyor Options

- Custom Door Options

- Solvent Applications

- Caustic Applications

- Water Applications

- Vapor Recovery

These units can typically process around 200+ drums an hour saving you both time and labor costs!

Read more about the DW-Series (drum washer) or DWC-Series (drum washer/crusher)designed to wash 55 Gallon Drums or 200 Liter Drums, Barrels, Pails, Buckets, Jars, Parts, Lids, and various other small to medium containers.

|

|

|

To read real SRS customer case studies on drum washers, click here

| |

To View Printable PDF Version of this Page ![]()

SRS Engineering Corporation is the leading manufacturer of drum washers and barrel washers. The DW-Series Drum Washers were designed for applications such as 55 gallon drum washing,44 gallon drum washing, 200 liter drum washing, 30 gallon drum washing, as well as bucket and pail washing. Custom solutions for industrial washing applications are also available.