CMP-Series Drum Compactor

The available Class 1, Division 1 motors and controls make the system suitable for use in hazardous areas including low level radiation applications. The CMP-Series generates 40,000 – 90,000 lbs. of compaction which crushes a standard 55 gallon drum to a 3 to 5 inch height, based on the model chosen (see Specifications Chart below). All CMP-Series Drum Crushers/Drum Compactors are all available in Electric, Pneumatic, and Gas versions.

Drum Crushers/Drum Compactors can be used in following industries:

Drum Crushers/Drum Compactors can be used in following industries:

- Manufacturing plants

- Processing Plants

- High-tech industries

- Treatment and disposal facilities

- Research laboratories

- Hospitals and medical clinics

- And more….

Features and Options Include:

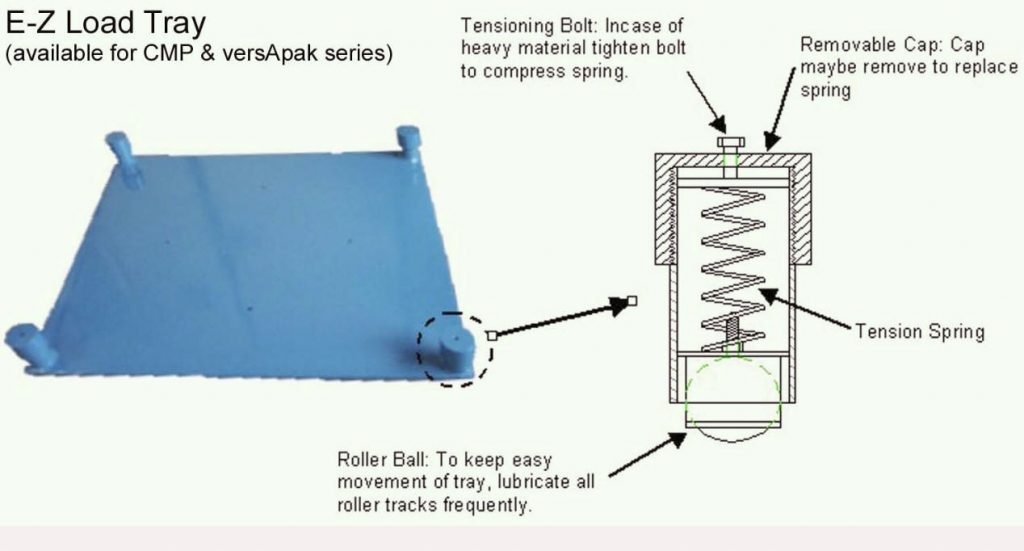

- EZ-Load barrel tray (see image below)

- Caster Wheels

- Liquid removal system

- Hazardous location (Explosion Resistant Package)

- Key starter

- Epoxy paint

- Weather covers

- VOC and dust filter system

- Tall drum chamber (For 85 gallon drums)

- Air filter systems HEPA/ULPA/Activated Carbon

- 12 x 14 guide sleeve for the cylinder

- 42″ stoke

- Optional Conveyors

- Auto cycle valve: Automatically returns the cylinder after crushing

- Hydraulic safety door sensor prevents operation when door is open

- Heavy gauge crushing chamber for durability

- Fork lift pockets for the ease of relocation and loading and unloading

- 20 gallon hydraulic oil reservoir

Click Video below to see how our drum crusher/drum compactor operates

- Electrical control box NEMA option for explosion proof applications

- Standard 230-460V, 3-phase, 50-60 HZ (Other voltage options available)

- 10-15 HP Motor

To Read Real SRS CMP-Series Customer Stories, CLICK HERE

| |

Compaction Ratio:

|

Specifications:

|

||||||||||||||||||||||||||||||||||||||||||

All of these units meet OSHA and JIC standards as well as CSA and UL standards.